After-Sales Service Notice for Turkey Region

After-Sales Service Notice for Turkey Region Dear Valued Customers and Partners, We are pleased to inform you that our professional after-sales service team will be deployed in Turkey this week to provide technical support and maintenance services for screen printing machines and related accessories. For our long-term valued customers: Should your equipment require maintenance, troubleshooting, or technical consultation, please feel free to contact us at your earliest convenience. Our team is fully equipped to address your needs promptly and ensure the stable operation of your machinery. For friends with potential future requirements: We warmly welcome you to inquire about our product series, technical specifications, and after-sales support system. We also offer face-to-face consultation appointments—this is an excellent opportunity to discuss customized solutions tailored to your production needs and establish in-depth cooperation. To ensure efficient service arrangement, please reach out to us via the following channels to confirm your needs or schedule an appointment: - Email: fany@lt-xm.com - Phone: +8618965820062 - WeChat/WhatsApp: +8618965820062 We look forward to connecting with you in Turkey and providing you with high-quality, reliable technical support and service experience. Best regards, LINGTIE (XIAMEN)MACHINERY CO.,LTD 2026-1-21

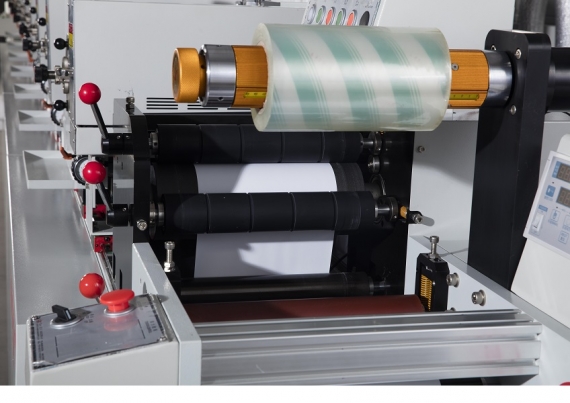

Mesin Cetak Kop Surat Rotary Intermittent

merek:

Lingtieitem no.:

LTAC-280pembayaran:

T/T, T/Charga pasar:

$99999pelabuhan pengiriman:

Xiamen ,China

Deskripsi Mesin Cetak Kop Surat Rotary Intermittent

- Sistem kontrol pencetakan full-servo untuk memastikan akurasi berjalan tinggi.

- Satu set stensil dapat dicetak dalam berbagai ukuran untuk menghemat biaya pencetakan.

- Sistem pelepasan tinta dapat mengontrol setiap kursi warna secara terpisah melalui layar sentuh, dan dapat memilih pembuangan tinta otomatis dan pembuangan tinta manual.

- Fungsi versi otomatis dapat sepenuhnya menghemat bahan dan waktu mesin, tidak perlu memperbaiki tempat warna secara manual; sistem akan secara otomatis memasuki keadaan terkunci setelah penyesuaian.

- Pelepasan tinta otomatis: Sistem secara otomatis menyesuaikan tegangan dan tinta di bawah kecepatan pencetakan yang berbeda untuk memastikan keselarasan yang akurat dan kualitas cetak yang sama.

- Perangkat pencetakan kedua untuk memenuhi proses pencetakan berulang pelanggan.

Parameter pencetakan label pencetakan tempel yang intermittent

- Max. lebar web : 350 mm

- Max. Area Percetakan: Intermiten Rotary: 50 ~ 305 (L) x 270 (w)

- Max. Area pencetakan: Full Rotary: 340 (w) x 376 (L)

- Max. Kecepatan: 30-200 RPM, 12000 imp / jam

- Catu daya: 3 fasa, 80 A, 15 kW

- Berat mesin: 3500 KG (N.W.), 4500 KG (G.W.)

- Dimensi instalasi mekanis: L 550 x W 120 x H 140 (CM)

Di mana untuk membeli Mesin Cetak Label Surat Percetakan Intermiten, beri tahu saya kebutuhan Anda, sisanya dapat kita kerjakan.

Lingtie (Xiamen) Machinery Co. Ltd. adalah perusahaan yang mengkhususkan diri dalam R & amp; D, Industri, CNC Machining, penjualan dan layanan Mesin Percetakan Label Letterpress, mesin cetak gulung gulung otomatis untuk sablon sutra, mesin rewinding, mesin rewinding label, roll -potong mesin potong dan peralatan tambahan selama 15 tahun. Jumlah total penjualan alat dapat mencapai 20 juta setiap tahun. Layanan Lingtie Machinery di seluruh dunia klien selama 15 tahun juga.

Berapa Harga dari Shaftless Intermittent Rotary Letterpress Label Printing Machine?

1. Beritahu kami berapa banyak warna yang ingin Anda cetak?

2. Beritahu kami jenis UV INK yang Anda gunakan, tinta UV berbasis minyak atau tinta UV berbasis air?

3. Berapa banyak fungsi yang ingin Anda tambahkan?

sebelumnya:

Mesin Cetak Label Letterpressberikutnya:

Mesin Cetak Rotary Letterpress

-

Mesin Cetak Label Letterpress

Mesin Cetak Label Letterpress

Mesin cetak tempel rotary tanpa intermiten shaftless membawa teknologi yang dipatenkan - Penyelarasan Plat Otomatis

-

Pencetakan Label Pencetakan Letterpress

Pencetakan Label Pencetakan Letterpress

Intermiten pencetakan Label Pencetakan Rotary Tekan membawa teknologi yang dipatenkan - Fungsi Pendaftaran Otomatis banyak digunakan dalam pencetakan stiker, pencetakan film.

-

Mesin Cetak Rotary Letterpress

Mesin Cetak Rotary Letterpress

Anda dapat memilih Full Rotary Intermittent Label Printing atau Semi-rotary Intermittent Printing sesuai dengan dimensi material Anda. Ini kecepatan pencetakan mencapai 200 RPM (73 meter / menit).

-

Mesin sablon panel PVC

Mesin sablon panel PVC

Mesin sablon panel PVC, Area pencetakan 400 * 500mm, cocok untuk pencetakan papan nama panel alat rumah.

hubungi kami : +86-18965820062

hubungi kami : +86-18965820062 e-mail : fany@lt-xm.com

e-mail : fany@lt-xm.com

Indonesia

Indonesia English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português Nederlands

Nederlands العربية

العربية 한국의

한국의 Türkçe

Türkçe Melayu

Melayu Polski

Polski magyar

magyar ไทย

ไทย Việt

Việt हिंदी

हिंदी Limba română

Limba română 中文

中文

+86-18965820062

+86-18965820062

+8618965820062

+8618965820062