After-Sales Service Notice for Turkey Region

After-Sales Service Notice for Turkey Region Dear Valued Customers and Partners, We are pleased to inform you that our professional after-sales service team will be deployed in Turkey this week to provide technical support and maintenance services for screen printing machines and related accessories. For our long-term valued customers: Should your equipment require maintenance, troubleshooting, or technical consultation, please feel free to contact us at your earliest convenience. Our team is fully equipped to address your needs promptly and ensure the stable operation of your machinery. For friends with potential future requirements: We warmly welcome you to inquire about our product series, technical specifications, and after-sales support system. We also offer face-to-face consultation appointments—this is an excellent opportunity to discuss customized solutions tailored to your production needs and establish in-depth cooperation. To ensure efficient service arrangement, please reach out to us via the following channels to confirm your needs or schedule an appointment: - Email: fany@lt-xm.com - Phone: +8618965820062 - WeChat/WhatsApp: +8618965820062 We look forward to connecting with you in Turkey and providing you with high-quality, reliable technical support and service experience. Best regards, LINGTIE (XIAMEN)MACHINERY CO.,LTD 2026-1-21

Mesin Cetak Rotary Letterpress

merek:

Lingtieitem no.:

LTAC-320Apembayaran:

T / T, T / Charga pasar:

$88888asal produk:

Chinapelabuhan pengiriman:

Xiamen,Chinalead time:

decide to the label printing press

Fitur untuk Mesin Cetak Label Percetakan Semi-putar Grosir

1. Sebuah silinder cetak dapat dicetak dalam berbagai ukuran, menghemat biaya pencetakan.

2. Stasiun pencetakan dapat mengontrol setiap kursi warna secara terpisah melalui layar sentuh, pembuangan tinta otomatis, dan pembuangan tinta manual dapat memilih.

3 Sistem register otomatis menghemat bahan dan menyesuaikan waktu mesin, tidak perlu secara manual memperbaiki stasiun warna, sistem akan secara otomatis memasuki keadaan terkunci.

4. Sistem pembuangan tinta otomatis menyesuaikan tegangan dan volume tinta di bawah kecepatan pencetakan yang berbeda untuk memastikan pendaftaran yang akurat dan kualitas pencetakan presisi tinggi yang sama.

5. Perangkat pencetakan kedua untuk memenuhi kebutuhan pencetakan berulang pelanggan.

6 Sistem kontrol servo lengkap menyediakan akurasi berjalan dan overprint tinggi.

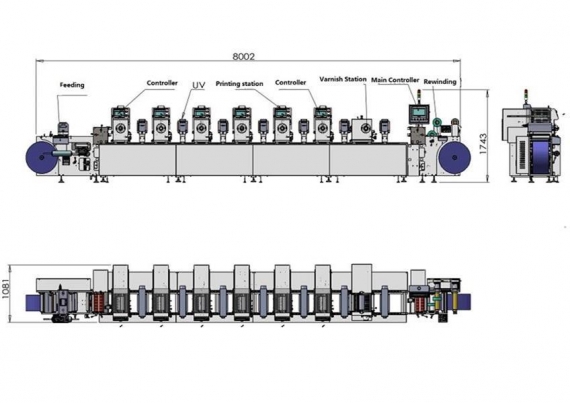

Spesifikasi Mesin Cetak Label Intermiten Dijual

Max. Lebar web: 320mm

Max. Area Percetakan: Intermiten Rotary: 50 ~ 305 (L) x 270 (w)

Max. Kecepatan Cetak: 200 RPM, 12000 imp / jam

Catu daya: 3 fasa, 80 A, 15 kW

Berat mesin: 3500 KG (N.W.), 4500 KG (G.W.)

Dimensi mekanis: L 550 x W 120 x H 140 (CM)

Fungsi Standar untuk 6 + 1 Shaft Mesin Cetak Rotary kurang intermiten

Transformator

Perangkat Tension Rewinding

Rol Layar (6 rol)

Pengering UV (6 stasiun)

2nd Pass Printing Unit

Mencetak silinder Setting Station

Mobil. Perangkat Pendaftaran (6 stasiun)

Unit penentuan pengaturan mikro (6 stasiun)

Web Guiding Feeder (Impor Perangkat dari Italia)

UV Center Control Case, Termasuk Sistem Melelahkan

Inker Roller (enam stasiun, Termasuk menghilangkan pencetakan tumpang tindih hantu Roller)

Fungsi Opsional:

Corona Device + Round Knife Die-cut Seat + Flexo Varnish Station + Laminating Rewinder + Stasiun Pendaftaran CCD + Eliminator Elektrostatik + Slitter & amp; Rewinder + Back Printing Station + Cold-stamping Station + Rewinding Machine + Flat Press die -cutting + stasiun sablon sutra

sebelumnya:

Mesin Cetak Kop Surat Rotary Intermittentberikutnya:

Pencetakan Label Pencetakan Letterpress

-

Mesin Cetak Label Letterpress

Mesin Cetak Label Letterpress

Mesin cetak tempel rotary tanpa intermiten shaftless membawa teknologi yang dipatenkan - Penyelarasan Plat Otomatis

-

Mesin Cetak Kop Surat Rotary Intermittent

Mesin Cetak Kop Surat Rotary Intermittent

Intermiten pencetakan label cetak Rotary Tekan membawa teknologi yang dipatenkan - Automatic Plate A? Lignment selama 15 tahun pengalaman profesional.

-

Pencetakan Label Pencetakan Letterpress

Pencetakan Label Pencetakan Letterpress

Intermiten pencetakan Label Pencetakan Rotary Tekan membawa teknologi yang dipatenkan - Fungsi Pendaftaran Otomatis banyak digunakan dalam pencetakan stiker, pencetakan film.

-

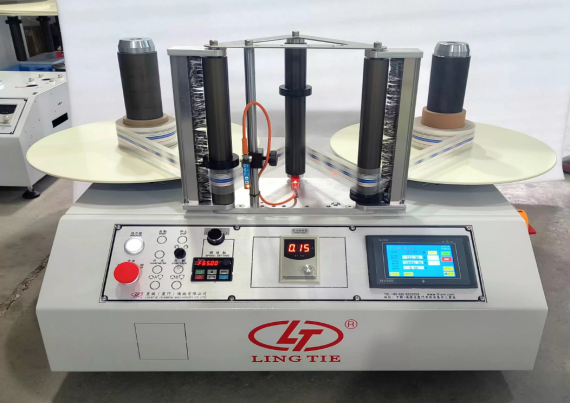

elektrostatik menghilangkan rewinder

elektrostatik menghilangkan rewinder

Mesin penggulung label umumnya digunakan dalam industri yang membutuhkan proses pelabelan dan pengemasan yang efisien. Beberapa industri yang seringkali membutuhkan mesin penggulung label untuk menunjang produksinya.

hubungi kami : +86-18965820062

hubungi kami : +86-18965820062 e-mail : fany@lt-xm.com

e-mail : fany@lt-xm.com

Indonesia

Indonesia English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português Nederlands

Nederlands العربية

العربية 한국의

한국의 Türkçe

Türkçe Melayu

Melayu Polski

Polski magyar

magyar ไทย

ไทย Việt

Việt हिंदी

हिंदी Limba română

Limba română 中文

中文

+86-18965820062

+86-18965820062

+8618965820062

+8618965820062